Today I am writing about flow measurement techniques

The only direct way of measuring flow is to collect the total discharge in a calibrated container or in a weighing

Gauging:

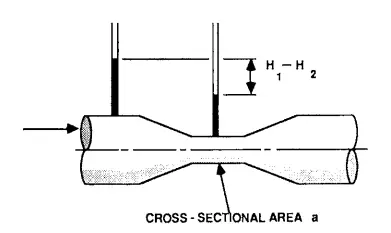

A common and accurate method of flow measurement is to pass the flow through or over a structure which has a known head-discharge relationship. For closed pipes or conduits running under pressure, venturi meters or orifice plates are the normal means of flow measurement. These rely on using the differential pressure across the device to determine the flow. Thus for a venturi meter the discharge is given by

Q = C a [ 2g (H1 – H2) ] 0.5

Where

Q = flow

C = discharge coefficient

a = cross-sectional area of throat

g = acceleration due to gravity

H1 – H2 = pressure difference between inlet and throat

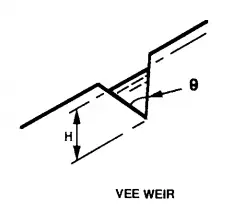

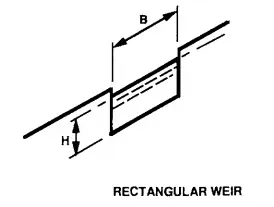

For open channels, flows can be determined using venturi flumes, sharp-edged rectangular or vee weir plates, broad crested weirs or triangular profile weirs. The basic equations for thin plate weirs, ignoring approach velocity effects, are

Vee notch

Q=0.53 tan (θ/2) (2g)0.5 H2.5

Rectangular notch

Q = 0.67 B (2g)0.5 H1.5

Where

θ = angle subtended by notch

H = head over notch

B = width of rectangular notch

Measurement of head is usually by means of a float in a stilling well upstream of the structure or with an ultrasonic level detector. Gauging structures can be costly to construct and can cause undesirable restrictions to the flow, so that in many circumstances they may not be appropriate and one of the other flow-gauging techniques must be used.

Velocity measurements:

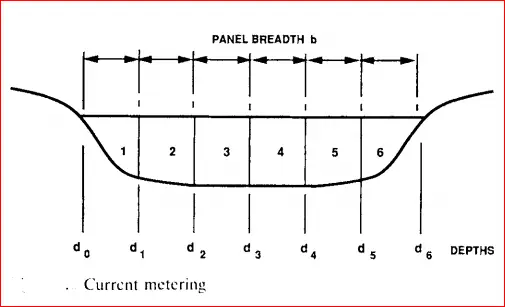

Since discharge is the product of velocity and cross-sectional area, it is clearly possible to determine discharge in a channel or pipe by measuring the velocity in a known cross-section. In practice the situation is complicated by the fact that velocity is not constant in a flow and in

Q = ∑ [(dn + dn+1) / 2] [(Vn + Vn+1) / 2] b

A newer technique for measuring mean velocity which is becoming increasingly popular employs ultrasonic beams which are transmitted at an angle across the channel and reflected back to a transmitter/receiver. Discontinuities in the flow reflect and attenuate the sound waves so that the pulses travelling in the two directions have slightly different timings due to the velocity of the water.